HARDOX® is a product of Svenskt Stål AB, a steel manufacturer based in Scandinavia and the United States.

HARDOX® has excellent wear resistance, allowing it to withstand long-term use in harsh environments and extending the replacement period of parts.

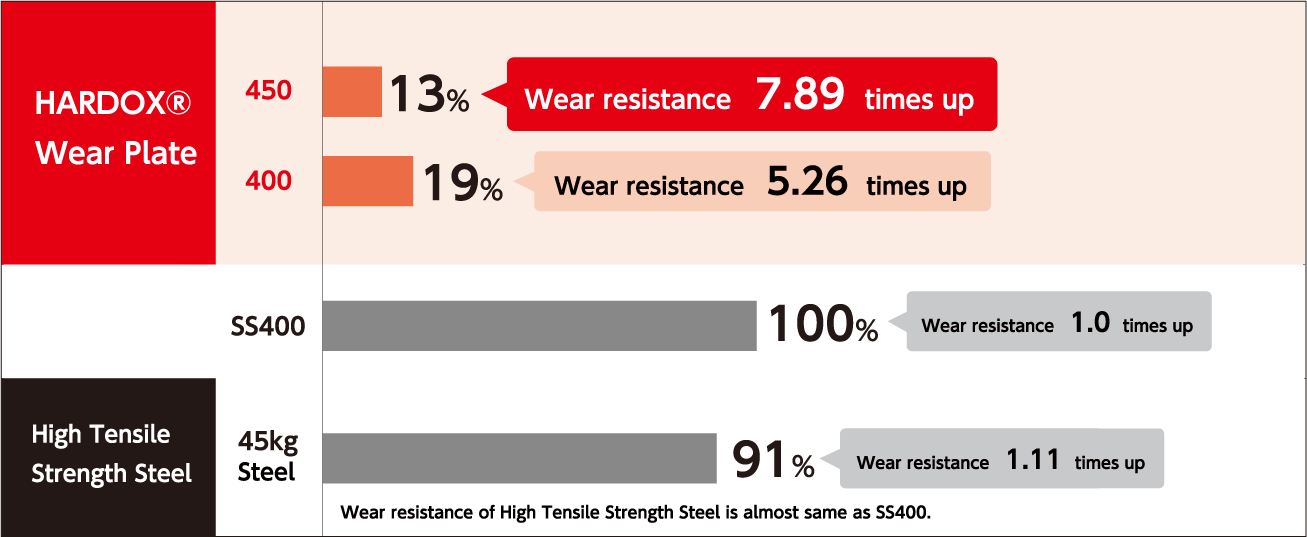

Comparison with other steel grades when the wear rate of SS400 is 100%.

With HARDOX®450,

wear rate is 13%,

wear resistance is improved 7.89 times!

|

HARDOX® WEAR PLATE |

Reference | |||

|---|---|---|---|---|---|

| 400 | 450 | SM490 | SM570 | ||

| Mechanical Strength Tensile(N/㎜²) | 1,250 | 1,400 | 490~610 | 520~720 | |

| Hardness | (HB) | 400 | 450 | Approx. 145~150 |

Approx. 180~190 |

| (HRC) | 43 | 46 | 0 (Assuming a tensile strength of 520N㎜²) |

8~9 (Assuming a tensile strength of 610N㎜²) |

|

| Value of impact energy -40℃(※) | 45J | 40J | 27J/0° | ||

※A measure of tenacity, the higher the number, the more tenacious.

|

HARDOX® WEAR PLATE |

||

|---|---|---|---|

| 400 | 450 | ||

| Mechanical Strength Tensile(N/㎜²) | 1,250 | 1,400 | |

| Hardness | (HB) | 400 | 450 |

| (HRC) | 43 | 46 | |

| Value of impact energy -40℃(※) | 45J | 40J | |

|

Reference | ||

|---|---|---|---|

| SM490 | SM570 | ||

| Mechanical Strength Tensile(N/㎜²) | 490~610 | 520~720 | |

| Hardness | (HB) | Approx. 145~150 |

Approx. 180~190 |

| (HRC) | 0 (Assuming a tensile strength of 520N㎜²) |

8~9 (Assuming a tensile strength of 610N㎜²) |

|

| Value of impact energy -40℃(※) | 27J/0° | ||

※A measure of tenacity, the higher the number, the more tenacious.

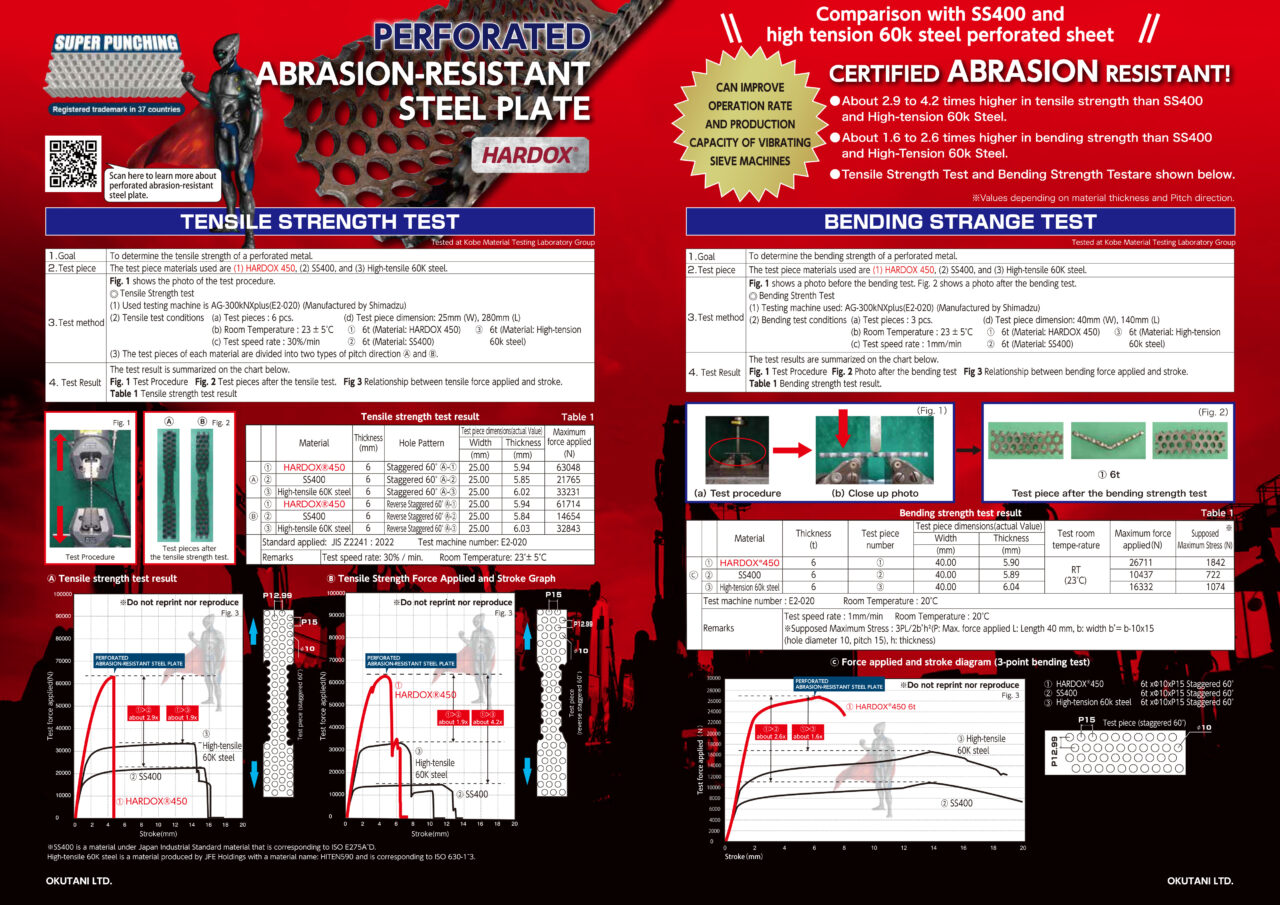

| Thickness | Hole size | Pitch | Pattern | Open area | Max. sheet size |

|---|---|---|---|---|---|

| 4.0t | 10Φ | 15 | 60°staggered | 40.3% | 914×914 |

| 4.0t | 15Φ | 20 | 60°staggered | 51.0% | 914×1829 |

| 6.0t | 10Φ | 15 | 60°staggered | 40.3% | 914×914 |

| 6.0t | 15Φ | 20 | 60°staggered | 51.0% | 914×1829 |

●For more details, please see the PDF file for a larger version.

<Manufacturer and Distributor>

OKUTANI Ltd.