Type of Wire Cloth

The best-suited type of wire cloth should be selected from those listed below, depending on the particular size of particles, workload, type of apparatus used, etc.

| Type of Wire Cloth |

Materials |

Remarks |

| Square Openings |

Plain Weave |

Stainless steel,

hard steel,

iron, etc. |

For mesh and wire diameters,

please refer to pages of particular products. |

| Intermediate Crimp |

| Lock Crimp |

| Flat Top Crimp |

| Slotted Openings |

Oblong Openings |

| Triple Shoot |

Selecting a Wire Cloth

A.Material of Wire

Such material should be selected that has a high tensile strength sufficient to resist a secondary breakage due to vibration and wearing due to abrasion with objects to be sifted, and a corrosion resistance should also be taken into consideration.

| Materials |

Code |

Tensile Strength kg/mm2 |

| Stainless Steel |

SUS-316 |

1.0mmΦ=60~75 |

5.0mmΦ=60~70 |

| SUS-304 |

2.0mmΦ=65~80 |

5.0mmΦ=60~70 |

| SUS-430 |

3.0mmΦ=50~60 |

5.0mmΦ=60~70 |

| SUS-410 |

4.0mmΦ=50~60 |

5.0mmΦ=60~70 |

| High Manganese Steel |

MM-2, Daido Steel |

5.0mmΦ=90~100 |

8.0mmΦ=100~110 |

| Hard Steel |

SWRH-4A |

5.0mmΦ=140~165 |

8.0mmΦ=125~150 |

| SWRH-2 |

4.0mmΦ=115~135 |

5.0mmΦ=110~135 |

| SWRH-5A |

3.0mmΦ=155~170 |

5.0mmΦ=160~180 |

| Piano Wire |

SWRS-2A |

2.0mmΦ=170~205 |

5.0mmΦ=170~190 |

| Mild Steel |

SWRM-2 |

1.0mmΦ=30~50 |

5.0mmΦ=30~50 |

|

|

●Carbon 60 corresponds to SWRH-4A

|

B.Weaving Style

- Coarse to medium-size particles: Intermediate Crimp, Flat Top Crimp

- Small to fine particles: Plain Weave, Twilled Weave, Slotted Openings

- Sticky and/or cloggy objects: Slotted Openings, Triple Shoot

- Very wet objects: Wedge Wire

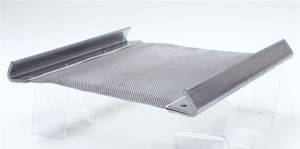

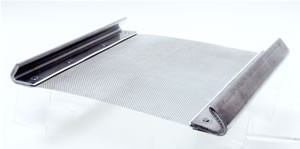

3.Size of Vibrating Screen

W=Width of screen

L=Length of screen

HL=Length of hook

HE=Length of portion without hook

(Overlap of wire cloths is generally about 20 mm.)

4.Location of Hooks

Such wire cloths with oblong openings as Slotted Openings screens can be provided in two different types, as shown in the figures, depending on the orientation of openings and location of hooks.

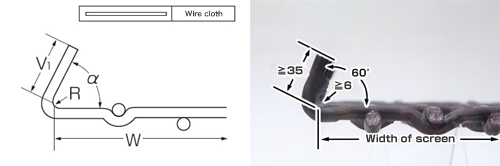

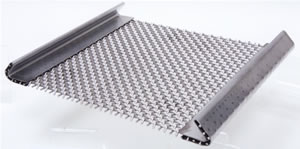

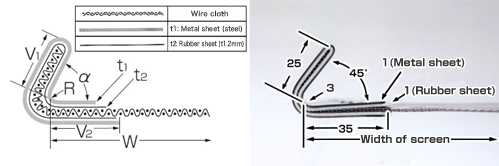

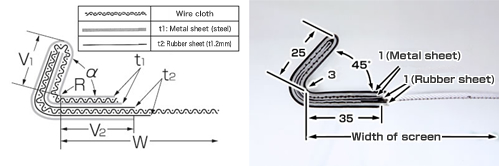

5.Type of Hook

Wire cloths used in vibrating screens are provided in each side with a hook for the purpose of :

- facilitating attachment and removal;

- reinforcing edges of the screen;

- tensioning the screen to prevent "sagging".

Five different specifications shown below are available according to wire diameters.

| Specification |

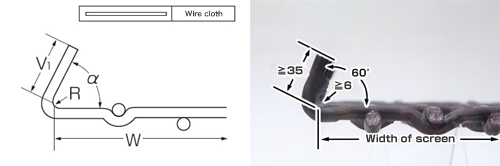

Hook Type No.1 |

| No.1 |

|

| Structure of Hook |

|

| Dimensions |

V1 |

V2 |

α |

R |

t1 |

t2 |

| ≥35 |

- |

60° |

≥6 |

- |

- |

| Remarks |

For wires diameters of 6.0 mm or more. |

|

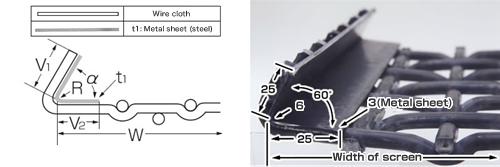

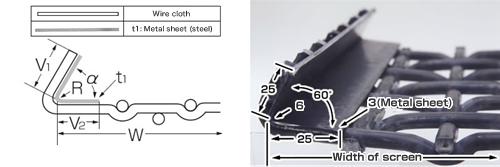

| Specification |

Hook Type No.2 |

| No.2 |

|

| Hook Type |

|

| Dimensions |

V1 |

V2 |

α |

R |

t1 |

t2 |

| 25 |

25 |

60° |

6 |

3 |

- |

| Remarks |

For wire diameters of 4.0 mm or more and less than 6.0 mm with a metal sheet (t1). |

|

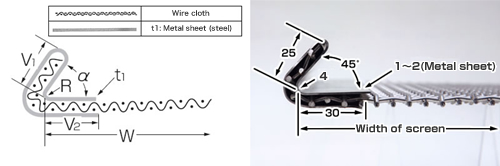

| Specification |

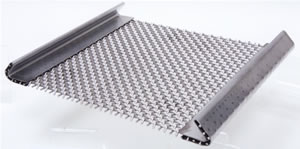

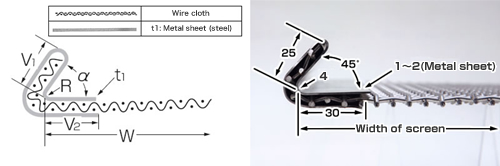

Hook Type No.3 |

| No.3 |

|

| Hook Type |

|

| Dimensions |

V1 |

V2 |

α |

R |

t1 |

t2 |

| 25 |

30 |

45° |

4 |

1~1.2 |

- |

| Remarks |

For wire diameters of 1.0 mm or more and less than 4.0 mm with a metal sheet (t1). |

|

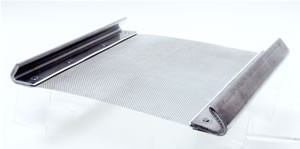

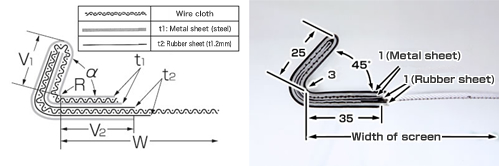

| Specification |

Hook Type No.4 |

| No.4 |

|

| Hook Type |

|

| Dimensions |

V1 |

V2 |

α |

R |

t1 |

t2 |

| 25 |

35 |

45° |

3 |

1 |

1 |

| Remarks |

For wire diameters of 0.5 mm or more and less than 1.0mm with a metal sheet (t1) and a rubber sheet (t2). |

|

| Specification |

Hook Type No.5 |

| No.5 |

|

| Hook Type |

|

| Dimensions |

V1 |

V2 |

α |

R |

t1 |

t2 |

| 25 |

35 |

45° |

3 |

1 |

1 |

| Remarks |

For wire diameter of less than 0.5 mm with a metal sheet (t1) and a rubber sheet (t2). |

|

Above listed are standard products, and rivets with patches are also available.

6.Screen Installation Tips

A.Proper tensioning

Improper tensioning will cause secondary vibration of the screen that often leads to breakage of the screen.

B.Tensioning method of the screen

Use of hooks for proper tensioning of the screen is recommended. Note that stretching the screen flat significantly affects its service life.

C.Proper arc of support bars

Support bars must be arranged in a proper arc shape. Otherwise, tensioning of the screen comes to be uneven, leading to breakage of the screen.

D.Constant tensioning

During operation, as the screen may become loose due to stretching and loosening of the hooks, it is important to check the screen, and retighten the hooks.