A wire mesh mist eliminator can be defined, in short, as a mist separator for collecting, separating and removing unwanted substances (impurities) entrained in a liquid or gas stream by means of wires forming the mist eliminator to increase the efficiency of separating (distillating and rectifying) operation.

A mist eliminator effects separation as a gas stream impinges against the eliminator. The stream of gas generated from a liquid moves up through the column (with fine particles of liquid entrained in the stream), and impinges against the mist eliminator. As the liquid particles entrained in the gas stream come into contact with the surface of the wires in the mist eliminator, they are temporarily retained there due to wettability and capillarity of the wires and the surface tension of the liquid before they grow to a larger size, and finally drop by gravity to the bottom of the column.

Stainless steel (SUS304, 304L, 316, 316L), titanium, aluminum, Inconel®, Monel®, nickel, copper, brass, polypropylene, grass fiber, PFA, Teflon®, Aflon®

| Absorbers |

| Crystallizers |

| Cooling Towers |

| Dehydraters |

| Distillation Columns |

| Evaporators |

| Fractionating Columns |

| Gas Absorbers |

| Gas Cleaners |

| Diffusion-Absorption Systems |

| Vacuum Distillation Systems |

| Wet Scrubbers |

| Dust Collectors |

| STYLE NO. | Void Ratio % | Surface Area m2/m | Density kg/m | Wire Diameter | Equivalent to |

|---|---|---|---|---|---|

| YORK | |||||

| SK-80 | 99.0 | 158 | 80 | 0.25φ | 931 |

| SK-144 | 98.2 | 280 | 144 | 0.25φ | 431 |

| SK-192 | 97.5 | 375 | 192 | 0.25φ | 421 |

| SW-216 | 97.2 | 905 | 216 | 0.12φ×6ply | |

| SW-432 | 94.5 | 1,780 | 432 | 0.12φ×12ply | 333 |

OK-450 φ0.12×2mm opening

Glass Wool

PP (polypropylene) φ0.25

Teflon® or PFA φ0.25

* A suitable form of mist eliminator should be selected for a particular application, location, and set of conditions.

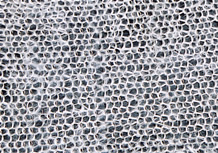

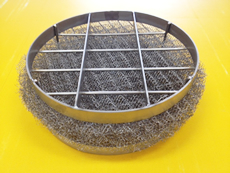

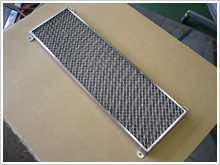

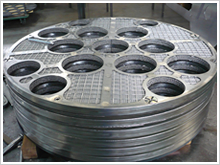

A specific thickness and diameter required for a particular application can be obtained, and the mist eliminator can be cut to sections for easy installation through a manhole of the tower. Layers of crimped wire meshes are stacked alternately, as shown in the picture, to a specified thickness and diameter.

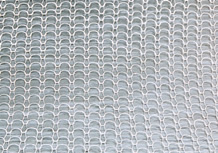

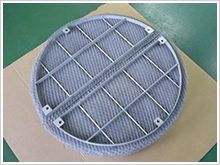

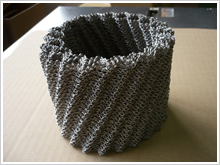

Produced to a specified diameter by winding crimped wire meshes with a required width.

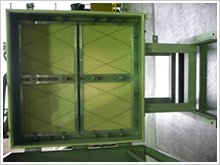

Used for small-sized not large-size towers.

|  |

|  |

|  |

|  |

|  |

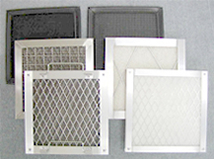

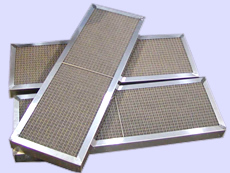

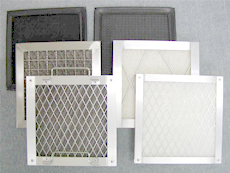

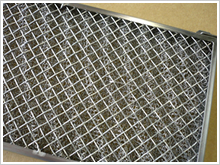

| Framed Mist Eliminators | PFA Mist Eliminator with Grids |

|  |

|  |

|  |

|  |

|  |